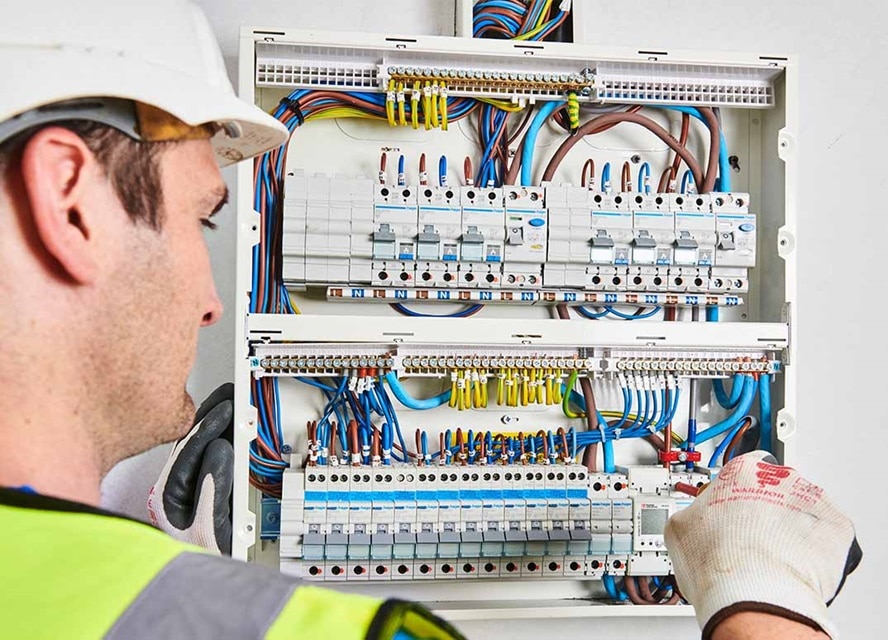

Protection Devices

Our technical training manager, Paul Collins discusses what contractors need to know in regards to electrical safety and the role RCDs and AFDDs play.

Electrical Safety Provided By RCDs and AFDDs

Paul Collins, Technical and Training Manager from Hager, covers what the professional contractor needs to know, including a recommendation that Type A RCD selection is the best answer for the majority of electric circuits.

Residual Current Devices (RCDs) are switches in the consumer unit that trip a circuit under dangerous conditions and instantly disconnect the electricity supply. They are an essential element when it comes to the protection of people and property and is required to be included to protect a diverse range of equipment from household appliances, lighting controls, IT and multimedia equipment and even the growing presence of charging solutions for electric vehicles.

RCDs have been in existence for a long time and the 18th Edition regulations further clarified their selection and specification to further enhance safety standards and ensure proper protection for all. Electrical contractors need to carefully consider the type of RCD required depending on the type of equipment which may be connected to the installation, as failing to do so could compromise safety and protection levels in the future.

There are four types of RCD, with each reacting differently depending on the presence of DC components or different frequencies. For contractors to specify the correct RCD, it is important they can differentiate between the options before them.

- Type AC RCD can detect and respond to AC sinusoidal residual current only.

- Type A RCD can detect alternating sinusoidal residual current and residual pulsating direct current suddenly applied or smoothly increasing. It is important to remember that Type A RCD is also suitable for Type AC applications. Type A RCDs are particularly suitable for equipment incorporating electric components

- Type F RCD can detect and respond to high-frequency residual current as well as pulsating DC residual current. Type F RCDs are suitable for equipment utilising frequency controlled speed drives

- Type B RCD can detect and respond to all types of residual current including smooth DC residual current. Type B RCDs are particularly suitable for use with electric vehicle chargers and PV supplies

Due to the style of circuits, the nature of loads connected to these circuits and the frequent use of RCDs to protect a group of circuits, Hager believes the majority of electrical circuits in residential and commercial applications require a Type A RCD solution. Not only is this the safest RCD solution, but it also provides the widest possible protection across a range of equipment and loads. In particular, this applies to single-phase equipment with electronic components and would typically comprise of many items such as, single-phase invertors, IT and multimedia equipment, power supplies for Class II equipment, appliances such as a washing machine that is not frequency-controlled, lighting controls such as dimmer switch and home and building electronic systems, induction hobs and electric vehicle charging where any smooth DC fault current is less than 6 mA.

Safety and protection when dealing with electrical installations have to be the number one priority for contractors and the reassurance that comes with fitting a Type A RCD solution ensures this objective can be achieved on all relevant projects.

AFDDs for added protection

Arc Fault Detection Devices (AFDDs) is recommended as a means of providing additional protection against fire caused by arc faults in AC final circuits. It is another level of protection for electrical circuits and further improves the safety standards for homes and commercial electrical installations.

An AFDD offers enhanced protection to complement measures already in place as they are designed to detect low level hazardous arcing which other devices such as circuit breakers, fuses and RCDs are not able to detect.

If used, the AFDD should be placed at the origin of the circuit to be protected and some primary examples of where such devices can be used include:

- Premises with sleeping accommodation

- Locations with a risk of fire due to the nature of processed or stored materials such as woodworking shops or stores on combustible materials

- Locations with combustible construction materials such as wooden buildings

- Fire propagating structures

- Locations housing irreplaceable goods.