AFDD

Arc Fault Detection Device

An AFDD will trip the circuit when a potentially hazardous arc occurs, eliminating the resulting fire hazard.

What is the role of AFDD?

Typical causes of arc faults

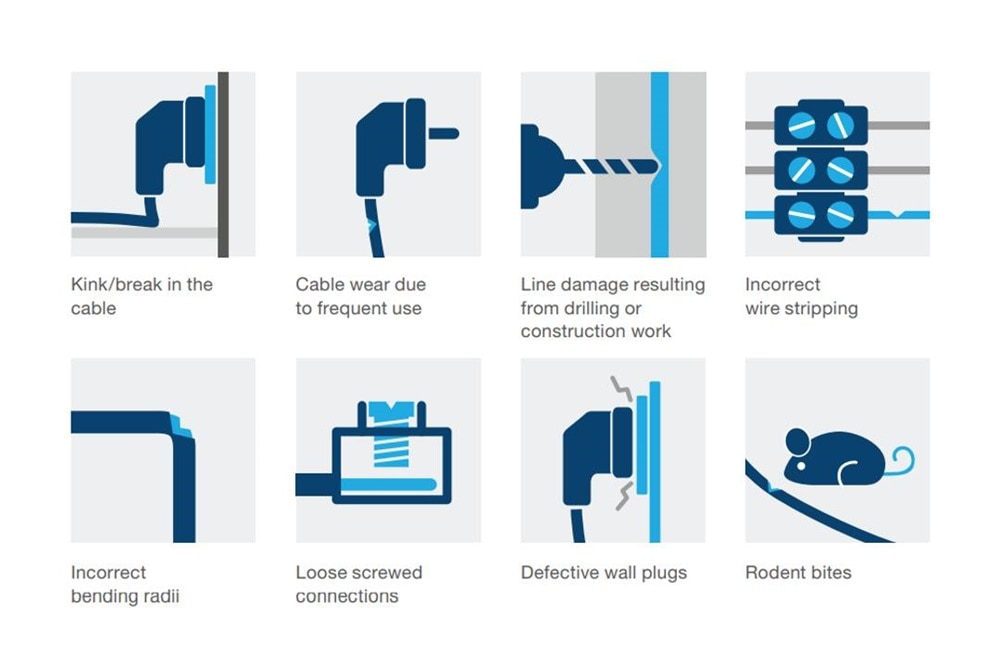

The graphic is intended to give you a brief overview of faults that lead to arcing faults, which in turn can cause fires. Virtually anywhere there is damage to live wiring that does not break the circuit, an arc can occur that can then set surrounding materials on fire.

Some errors, such as cable damage caused by drilling or cable kinks/cable breaks, occur immediately and can sometimes be easily identified and rectified. Other errors only develop over time and are usually not directly noticeable.

A terminal point, for example, is not usually subject to constant testing. Temperature-related expansion and corrosion can loosen contact with the cable. An arcing fault can occur over the resulting gap. Cable wear, in turn, is caused by frequent use and improper handling of lines and cables. Although damage can be detected here, experience shows that devices with defective cables are often still in use because the people who use these devices are not sufficiently aware of the resulting dangers.

How does it work?

In an intact circuit, the parameters are only brought into ranges that trigger the AFDD in exceptional cases. So-called operating arcs are able to influence the sine waves in such a way that they have a waveform similar to an arc fault. These arcs form, for example, in the brush spark of a drill and in electronic components and even light switches that cause arcs when switching. However, the AFD units from Hager are able to distinguish between operating arcs and fault arcs and only switch off in the event of a fault.

Practical information for your daily work

Standard and application

What does DIN VDE 0100-420 regulate?

DIN VDE0100-420 regulates the use of measures to protect against the thermal effects of arcing in final circuits.

How do you prevent fires that can be caused by arcing faults?

Further details can be found simply and in summary on our information page on the DIN VDE0100-420 standard.