Modular Circuit Protection

FAQs

How can we help you?

What do MCB Trip Curves or Time Current Curves mean?

Trip curves are used to show the trip current rating of the Miniature Circuit Breakers (MCBs). The trip current rating is the minimum current level at which the MCB will trip instantaneously.

There are three Hager MCB curve characteristics for magnetic operation to provide short-time protection against short circuits:

B - 3-5 times line current used on generators, EVCS and long runs, not commonly used in Australia.

C - 5-10 times, light and power circuits, most commonly installed in residential light commercial, widely available.

D - 10-20 times, highly inductive load, motors, transformers, some discharge lighting, welders. most commonly installed for motors and in industrial applications.

What accessories can be fitted to Hager MCBs?

Hager's MCB Accessories include auxiliary contacts (on/off condition), signal contacts (MCB tripped due to fault), shunt trip (remote operation off), undervoltage (35-70% of nominal causes MCB to trip), locking device, and heat dissipation inserts.

What affect does ambient temperature have on MCB operation?

All MCBs have thermal/magnetic characteristics that are affected by ambient temperature. Refer to the Hager MCB Technical Information, temperate derating when installing Hager MCBs in ambient temperatures other than 30°C.

What does the kA rating of a MCB imply?

All Hager MCBs have been subjected to short circuit testing at their marked kA rating and are capable of successfully interrupting the fault current without undue damage to the circuit or MCB.

However, the MCB should not be installed into an area where the prospective fault level is higher than the kA rating of the MCB (except where cascading is used as a design feature under Clause 2.5.7.2.1 of the Wiring Rules). Commercial installations and installations close to distribution transformers will have relatively higher fault levels. Consult the energy distributor for the upstream fault level / kA at a given installation.

What is a RCB/RCCB/RCBO?

RCD stands for Residual Current Device, while RCB stands for Residual Current Breaker, RCCB stands for Residual Current Circuit Breaker. These are all terms for the same type of circuit breaker or protection device.

RCB is an electrical protection device that disconnects the circuit as soon as it detects a current leak to the earth. It also protects against electric electrocution or shock caused by direct contact, but does not provide overcurrent protection.

RCBOs combine the functions of RCD and MCB, into a Residual Current circuit Breaker with Overload device.

RCBO and RCCBs, are both residual current protection devices.

This protection is achieved by monitoring the current flow in the line and neutral. In a healthy circuit, the current flow via the line equals the return flow in the neutral.

However, this return flow may not be equal to the line’s current flow in the event of any abnormalities. A residual current device will sense such a scenario and interrupt the circuit.

What is a Type A RCCB/RCBO?

Type AC RCCB/RCBOs are sensitive to AC sine waves only, but are to be phased out in Australia by 2023 Type A RCCB/RCBOs are sensitive to both AC and pulsating DC sine waves.

Can I connect a Hager Residual Current Device (RCD) to a DC supply?

No. Hager RCCBs and RCBOs are not suitable for DC applications.

RCD / RCBO Nuisance tripping or Unwanted tripping cause and remedies.

It is very tempting to describe RCD/RCBO tripping due to intermittent electrical fault as ‘Nuisance Tripping’.

However, ‘Nuisance Tripping’ probably should really only be used when an RCD/RCBO trips for no electrically based reason.

Intermittent tripping that typically occurs after a new installation, maintenance or wiring modification would suggest that the RCD/RCBO is performing the very function for which it was designed / installed for (i.e. fault detection & protection). This intermittent or ‘Unwanted Tripping’ can actually highlight potential problems within the installation, turning the simple exercise of fitting of an RCD, into a huge fault finding exercise.

Typically ‘Unwanted Tripping’ on RCDs/RCBOs can stem from misplaced or combined Neutrals.

At times, Neutrals intended for protection by the RCD are incorrectly wired to the ‘pre-RCD’ Neutral bar. Other times, current is accidentally shared between the ‘pre-RCD’ Neutral bar and ‘post-RCD' Neutral bar (e.g. via a common bond that should not exist in the first place).

Another important consideration is the effect of Standing Leakage Current & how it relates to ‘Unwanted Tripping’ (Refer to FAQ – Standing Leakage Current…..).

Standing Leakage Current & how it relates to Unwanted Tripping on RCDs.

Standing Leakage Current is inherently present in all electrical appliances due to the RFI filters and suppressors inside switch mode power supplies on modern appliances such as LCD TVs, Hi-fi systems, PCs and Laptops. This also occurs in leaky cable appliances with pre-existing poor insulation resistance, or an insulation breakdown developed over time.

Typically ‘Unwanted Tripping’ is blamed on the RCD being overly sensitive. More often than not, it is the Standing Leakage Current that is the problem. The steady state sum of Standing Leakage Current in the circuit must be significantly less than the RCD tripping threshold. If this is very close to the RCD tripping threshold, then even the slightest transient disturbance will cause the RCD to trip.

Generally, RCDs may trip at any value in excess of 50% of the rated residual current (e.g. 15mA on 30mA RCD). Further care should be taken on installations that are susceptible to high transient disturbances or where particularly leaky appliances may be connected. The recommended Standing Leakage Current steady state threshold is less than 33% of the rated residual current (i.e. 10mA on 30mA RCD).

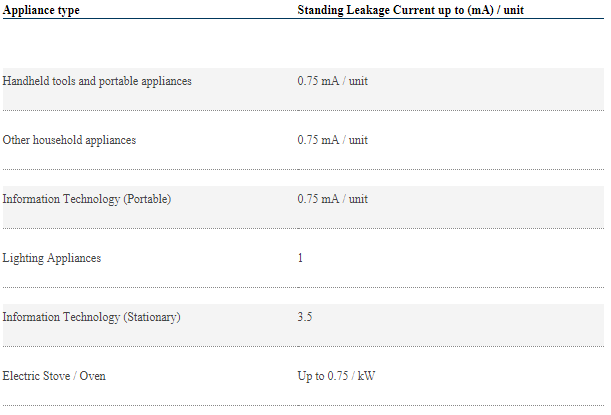

A list of appliance types and corresponding Standing Leakage Currents per unit are listed below:

| Appliance type | Standing Leakage Current up to (mA) / unit |

| Handheld tools and portable appliances | 0.75 mA / unit |

| Other houehold appliances | 0.75 mA / unit |

| Information Technology (Portable) | 0.75 mA / unit |

| Lighting Appliances | 1 |

| Information Technology (Stationary) | 3,5 |

| Electric Stove / Oven | Up to 0.75 / kW |

As an example, for a 30mA RCD to stay under the threshold and avoid ‘Unwanted Tripping’, it is recommended that a maximum of four computers (desktops/towers) are connected to a single RCD circuit at any one time. The number of computers may need to be further reduced if they have particularly high Standing Leakage Current or where the installation is particularly susceptible to transient disturbances.

I was using SPN**** SPDs, what is the new part number scheme, and do I have to swap to the new range straight away?

- Most part numbers have a simple transition SPN* -> SPB* - e.g., SPN 140D -> SPB140D

- Parts ending in ‘R’ continue to have remote contact.

- There is no direct replacement for the SPN115D/R - 15kA device. We suggest transitioning customers to a 40kA type.

- Replacement SPN cartridges are currently available.

Are the older Hager SPN* style SPDs compatible with the new SPB* range?

The SPB and SPN will ‘work’ next to each other and cascade between each other:

- But the SPN / SPB cartridges are not interchangeable,

- The SPN And SPB ‘R’ type contactors connectors are physically the same but have different terminal wiring configuration.

I have a project or quote that will require a large volume of SPDs, what should I do?

- Please check with the customer service team to ensure ensure adequate and appropiate stock can be supplied to the customer.

- Please note the new 3 Phase SPDs are cheaper than the equivalent three single devices.

How often should I inspect Surge Protective Devices?

Hager recommends inspection annually and after any storm event.

Ongoing, effective operation can also be confirmed by installing SPDs with a contact and wiring this contact to a BMS or other means to create an external audio or visual alarm on SPD fault.

Can I determine how long an SPD will last?

No, given the inherently unpredictable nature of surges and storms.

However, selecting the appropiate grade of SPDs for the risk condition at a given installation will reduce downtime and costs.

What test or maintenance should be carried out on Surge Protective Devices?

– Earthing resistance test (megger) to confirm low resistance path to earth via earth stake.

– Does the install comply with the following requirements?

- Minimum conductor cross-sectional area

- Correct size and function of overcurrent Fuse or MCB

- Surge protective devices in good mechanical condition, cartridges aligned and seated.

- Any available status indicators show functionality – there should be no prominent RED indicator.

Where are Hager SPB SPD devices manufactured?

Germany.

Do I have to use SPDs in my main switchboard (MSB) and distribution boards (DB)?

SPDs are not currently mandatory in Australia, but they are recommended in AS:3000 and AS:1768-

- Installing several SPD devices to create a Surge Protection system is proven to be a more effective approach to surge damage mitigation, as lighting and surges may occur anywhere in an electrical installation.

- Additionally, by installing SPD in multiple locations, including the MSB, DB and load centres, surge damage may be contained and mitigated from transversing further through the electrical installation.

Why do some SPDs come with a contact, and what is it for?

- Hager SPDs with part numbers that end in the letter ‘R’ have a removeable three wire contact.

- This to allow for external remote status indication, via an additional light, alarm or BMS input.

- This option is not available for ‘Fine’ SPDs

- The contact ‘R’ version SPDs are slightly more expensive than non-contact version SPDs, as there are more internal parts.

For three phase circuits, can I use three or four single pole SPDs instead of one three or four pole SPDs?

Yes, multiple single pole SPDs can continue to be used, but the new Hager three phase SPD devices are more cost effective.

Do you have diagrams that show me exactly how to wire SPD for residential or commercial applications?

Hager as a manufacturer provides example wiring diagrams and broad guidance, however only a licensed electrician can ensure all the variables and requirements of any given electrical installation are installed appropriately.

Do SPDs require an Australian RCM mark?

Surge devices are not on the declared list of electrical articles in Australia, and therefore do not require RCM approval.

Can I use SPA212A / SPA412A Spark Gaps without other SPDs?

No, to ensure a good level of protection for downstream installations and devices, the lightning gap device SPA212A and SPA412A should always be used with additional downstream T2 surge voltage arresters.

-

Type 1 Spark gap devices are optimized for the diversion of high-energy lightning currents (10/350 µs). - Type 2 Surge Protective Devices with varistors - (Hager Very Coarse, Coarse, Medium, Fine) are optimised for the diversion of low-energy to medium-energy surge currents and overvoltages (8/120 µs).

- The ability of Type 2 SPDs to repeatably discharge high-energy lightning currents (10/350 µs) is limited.

What is the difference between a three module and four module SPD, are they both suitable for three phase installations?

Both three and four module SPD devices are suitable for 3 phase circuits.

- Four module SPD devices have an additional Neutral cartridge and are only required when the device is not in proximity to a MEN link.

- A three module SPD is usually installed at the point of supply / MSB, while four module devices are appropriate for sub-distribution boards.

Do I need an SPD device with a Neutral cartridge?

No, not if the SPD is to be installed close to a MEN link.

A one or three module TN-C device is sufficient.– Only TN-S style SPDs have a Neutral cartridge, and the TN-S style should be used when the SPD is installed further than 10 metres from the MEN point, or in dedicated TN-S installations.

How do I know what part number SPD replacement cartridges are required?

The cartridge part number(s) are clearly marked on the front of each of the SPB cartridges, this information is the technical documentation provided with each device, this approach is the same as previous SPN products.

Why are the kA ratings different on some device cartridges, for example the SPB208D pictured below?

This is only for SPB TN-S products that have a Neutral cartridge. - This is because the Neutral cartridge (cartridges with part numbers ending in N) use a different technology to Line.

Can we install ‘Fine’ protection devices (SPB208D and SPB408D) only?

- Hager ‘Fine’ grade SPDs should not be used as the only SPD on an installation.

- Hager SPB ‘Fine’ grade SPDs are designed for final sub circuit protection and should be installed downstream of higher rated SPDs - such as ‘Medium’ or ‘Coarse’– It is acceptable to only use ‘Fine’ protection devices in final load centres and distribution points if there is cascading surge protection upstream.

What size SPD fuse or MCB do I need?

- Hager provides guidance on maximum SPD overcurrent fuse and MCB ratings, this is included with the documentation with each SPD device.

- However the SPD overcurrent device also needs to be less than the rating of the specific installations’ immediate upstream protective device.

- It is important that the recommended rating of overcurrent device is used as this ensures that it will function properly.- Disconnect safely and as fast as possible if the SPD fails.- Be able to carry expected surge impulse currents without failing.

- The second point is very important for the performance of an SPD. By lowering the backup fuse, you decrease the expected arrested surge current of the SPD.

How do I know if I need to replace an SPB SPD cartridge?

- Overall if the colour changes to a distinct Red, additionally if the ‘pin’ at the back of the cartridge is retracted then the cartridge should be replaced.

- For Very Coarse (100kA) and Coarse (65kA) SPB SPDs - a small oval indicator will change colours from Green (Ok) to Red (Faulty)

- For Medium (40kA) and Fine (8kA) SPB SPDs - a rectangular window is present, when this window is distinct or bright red, there is a fault

- Please note these rectangular style fault indicators may look somewhat red, or red tinged when new.

- To confirm the SPD condition, please check the pin at the back of the removed cartridge, as highlighted in the right picture above.

- If this ‘pin’ is protruding outside and visible, then the SPD cartridge is in good condition.

- If the SPD is Faulty or EOL, this ‘pin’ disappears (retracts).